Mastering Wood Concrete Forms: Essential Tips for Durable Construction

Wood concrete forms are foundational tools in construction, acting as molds to shape freshly poured concrete into desired structures. These forms, typically made from materials like plywood or lumber, are not only cost-effective but also adaptable to various architectural designs. This article explores the significance of wood concrete forms, offering detailed insights into their selection, usage, and maintenance to ensure optimal results in construction projects.

Choosing the Right Wood Concrete Forms

Material Quality

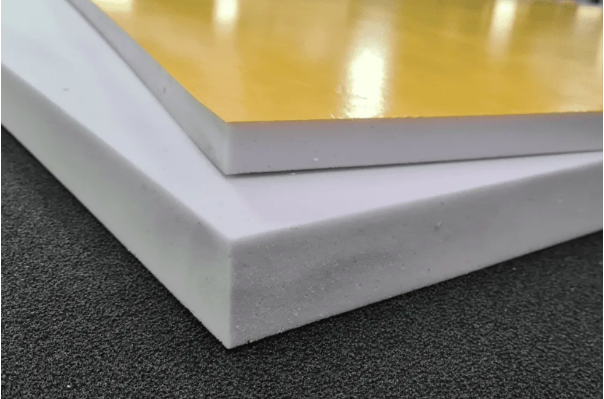

The choice of material significantly affects the durability and reusability of wood concrete forms. Plywood is a popular choice due to its smooth surface that imparts a flat finish to the concrete. For heavier loads, however, denser lumber varieties provide better support. It is crucial to select high-quality, water-resistant wood to prevent warping and deterioration over time.

Size and Shape Adaptability

Wood forms must be adaptable to the specific dimensions and shapes required in construction projects. Customizable options allow builders to create complex and unique architectural features. The versatility of wood forms makes them suitable for everything from large-scale foundations to intricate decorative elements.

Best Practices for Setting Up Wood Concrete Forms

Accurate Measurement and Cutting

Precision in measuring and cutting wood forms is paramount to avoid gaps and misalignments that could compromise the structural integrity of the concrete. Tools like table saws and hand saws should be used with guides to ensure clean, straight cuts.

Secure Assembly

Assembling wood concrete forms requires meticulous attention to detail. Using strong, corrosion-resistant fasteners such as screws or nails ensures that the forms hold together under the pressure of wet concrete. Additionally, applying a release agent on the inner surfaces of the forms can prevent the concrete from sticking, facilitating easier removal after curing.

Maintenance and Reusability of Wood Forms

Cleaning and Storage

Proper maintenance extends the life of it. After each use, removing concrete residue and applying a protective sealant can safeguard the wood from moisture and decay. Storing the forms flat and undercover prevents warping and keeps them in good condition for future projects.

Inspection and Repair

Regular inspections help identify potential issues like cracks or wear that could affect performance. Repairing minor damages promptly and reinforcing weakened areas ensures that the forms remain reliable and effective for subsequent uses.

Environmental Considerations and Sustainability

Using wood, a natural and renewable resource, for concrete forms is environmentally advantageous. Opting for sustainably sourced wood and considering recycling or repurposing used forms can enhance the eco-friendliness of construction practices.

Conclusion

Wood concrete forms are invaluable in the construction industry, offering flexibility, efficiency, and cost-effectiveness. By adhering to best practices for their use and maintenance, builders can achieve superior and durable results. As the industry evolves, continuing innovations in form materials and techniques will further enhance the capabilities and sustainability of wood concrete forms.