Innovative Ways To Enhance Todo Coupling Efficiency In Tank Loading Operations

Efficient tank loading operations are vital across various industries, ensuring the safe and effective transfer of liquids and gases. Todo Coupling mechanisms, known for their reliability and safety, are integral to this process. Optimising the efficiency of these couplings can lead to significant improvements in operational performance. This article delves into innovative methods for enhancing the efficiency of Todo Coupling systems in tank loading operations. By exploring advanced automation technologies, high-quality materials, enhanced training protocols, and predictive maintenance strategies, we aim to provide comprehensive insights for achieving optimal efficiency and safety in tank loading procedures.

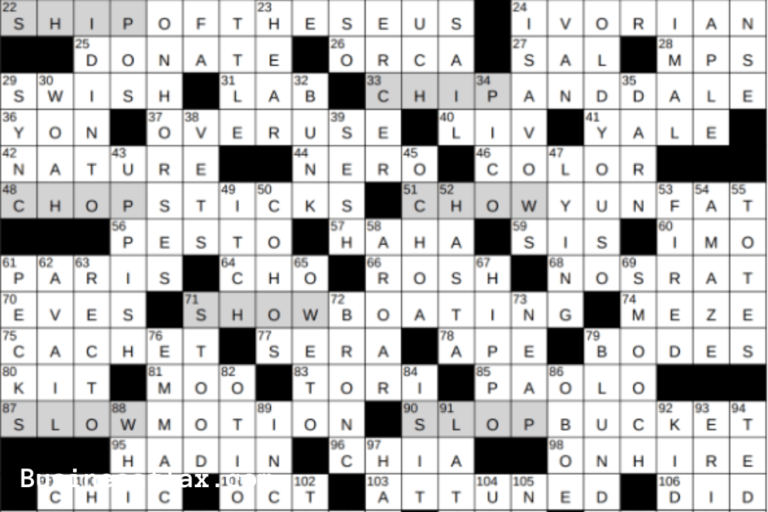

1. Understanding Todo Coupling Mechanisms

Todo Coupling mechanisms are essential for ensuring secure and leak-free connections between tanks and transport vehicles. To get the most out of Todo Coupling, it’s crucial to comprehend its working principles. A high-quality Todo Coupling system minimises the risk of spillage, which is vital for maintaining safety standards. Ensuring that the Todo Coupling is compatible with the types of fluids being transferred enhances overall efficiency. Additionally, regular maintenance checks on the Todo Coupling can prevent wear and tear, ensuring long-term reliability.

Understanding the specific requirements of different loading operations allows for the selection of the most suitable Todo Coupling. This not only improves efficiency but also enhances the safety and reliability of the operation.

2. Implementing Advanced Automation Technologies

Automation technology has revolutionised many industrial processes, and tank loading operations are no exception. Integrating advanced automation with Todo Coupling systems can significantly enhance efficiency. Automated systems can monitor and control the coupling process, reducing human error and increasing precision.

Sensors and automated control systems can detect potential issues before they escalate, ensuring smooth and uninterrupted operations. By automating the coupling process, companies can achieve faster loading times and better resource utilisation. Furthermore, automation allows for real-time data collection, enabling operators to make informed decisions quickly. This proactive approach can lead to substantial improvements in overall operational efficiency.

3. Utilising High-Quality Materials

The materials used in Todo Coupling systems play a crucial role in their performance and longevity. Using high-quality materials ensures that the couplings can withstand harsh operating conditions and resist wear and tear. Stainless steel, for example, is an excellent choice for couplings used in corrosive environments due to its durability and resistance to corrosion.

Regularly inspecting and replacing worn-out parts with high-quality components can prevent leaks and system failures. Investing in superior materials may have a higher initial cost but can result in significant savings in the long run due to reduced maintenance and replacement expenses. For more insights on the benefits of using high-quality materials in industrial equipment, check out this in-depth article on why material handling equipment is essential for your Business.

4. Enhancing Training And Safety Protocols

Even the most advanced Todo Coupling systems can only achieve optimal efficiency when operated by well-trained personnel. Comprehensive training programs ensure that operators understand the proper use and maintenance of the coupling systems. Training should cover all aspects of the coupling process, including installation, operation, and troubleshooting.

Implementing stringent safety protocols is equally important. Operators should be well-versed in emergency procedures and safety measures to handle any unforeseen issues. Regular safety drills and refresher courses can help maintain a high level of preparedness among the workforce. By fostering a culture of safety and continuous learning, companies can enhance the efficiency and reliability of their tank loading operations.

5. Adopting Predictive Maintenance Strategies

Predictive maintenance is an innovative approach that utilises data and analytics to predict when maintenance should be performed on Todo Coupling systems. By adopting predictive maintenance strategies, companies can identify potential issues before they lead to system failures. This approach not only improves efficiency but also extends the lifespan of the coupling systems.

Implementing predictive maintenance involves using sensors and monitoring equipment to collect data on the performance of the coupling systems. Advanced analytics tools can then analyse this data to detect patterns and predict when maintenance is needed. This proactive approach helps in avoiding unexpected downtime and ensures that the coupling systems are always in optimal condition. For more information on predictive maintenance, read this comprehensive guide on predictive maintenance.

Conclusion

Enhancing the efficiency of Todo Coupling in tank loading operations requires a multifaceted approach. Understanding the mechanisms of Todo Coupling, integrating advanced automation technologies, utilising high-quality materials, improving training and safety protocols, and adopting predictive maintenance strategies are all crucial steps. By implementing these innovative methods, companies can achieve significant improvements in their tank loading operations, ensuring safety, reliability, and cost-effectiveness.

This comprehensive approach not only enhances operational efficiency but also contributes to the overall success and sustainability of the industry. Adopting these best practices ensures that Todo Coupling systems perform at their best, providing a secure and efficient means of transferring liquids and gases in various industrial applications.

Read More: Puerto Vallarta